Understanding the Production Refine and Maintenance Practices for Aluminum Factory Products

The manufacturing procedure for aluminum factory items is complex and requires an extensive understanding of numerous phases. From the melting of aluminum at heats to different casting approaches, each action plays a vital duty. In addition, maintenance methods guarantee equipment remains efficient and items are cost-free from issues. The intricacies of these procedures and their impact on product high quality raising vital inquiries concerning best methods and innovative techniques in the market.

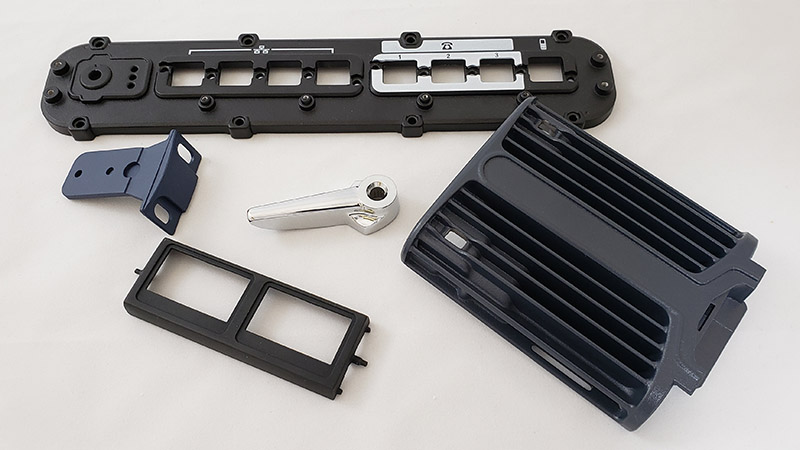

Review of Light Weight Aluminum Factory Products

Aluminum foundry items are essential parts in numerous sectors, supplying a blend of light-weight stamina and rust resistance. These items are generally made use of in industries such as auto, aerospace, and building and construction, where resilience and efficiency are critical. Aluminum's low density makes it an ideal product for applications requiring lowered weight without sacrificing architectural honesty. The flexibility of aluminum permits for the production of complex geometries, accommodating diverse layout demands.

In addition, aluminum shop products can be tailored with numerous alloys to enhance certain residential or commercial properties, such as boosted thermal conductivity or enhanced solidity. Their resistance to oxidation and rust assurances longevity, making them ideal for both interior and exterior applications. The combination of these features contributes to the growing choice for aluminum in contemporary production. As industries look for to enhance efficiency and sustainability, light weight aluminum foundry items remain to play an important function in fulfilling these demands.

Melting Refine: Changing Light Weight Aluminum

The melting procedure is an essential action in the manufacturing of aluminum foundry items, as it changes strong aluminum into a molten state suitable for casting. This procedure generally takes place in a furnace, where scrap aluminum or ingots are heated to temperature levels around 660 levels Celsius. The selection of heating system-- be it electrical, gas, or induction-- affects the performance and cost of melting.

Throughout melting, mindful factor to consider is given to the elimination of impurities, such as oxides and other impurities, which can adversely impact the top quality of the end product. Changes may be included to aid in this purification procedure, improving the fluidness of the molten steel.

In enhancement, temperature level control is vital to guarantee harmony and stop overheating, which can bring about oxidation. Subsequently, the melting process not only prepares light weight aluminum for spreading but additionally plays a considerable role in establishing the integrity and residential properties of the final factory items.

Casting Methods in Light Weight Aluminum Foundry

Numerous spreading strategies are employed in light weight aluminum foundries to develop high-quality components, each suited to different applications and specs. Among the most commonly made use of methods are sand casting, pass away casting, and investment spreading. Sand spreading utilizes a combination of sand and binder to form mold and mildews, enabling intricate shapes and large parts (Casting Foundry). Pass away casting, identified by the high-pressure injection of liquified aluminum right into steel mold and mildews, produces specific and repeatable components, perfect for automation. Financial investment casting, or lost-wax spreading, involves producing a wax version that is covered in a ceramic shell, enabling great information and complex designs. Each method has its advantages; sand spreading is economical for low-volume manufacturing, while die spreading uses efficiency for high-volume runs. Financial investment spreading is preferred for elements calling for extraordinary accuracy and surface finish. Choosing the appropriate technique depends upon aspects such as manufacturing quantity, component intricacy, and product properties

Finishing Procedures for Light Weight Aluminum Parts

After casting strategies have actually shaped the aluminum elements, completing procedures play a substantial role in boosting their performance and aesthetic allure. These processes commonly consist of machining, surface area therapy, and layer applications. Machining includes specific removal of material to attain wanted measurements and surface quality. This is crucial for guaranteeing that components fit flawlessly into their designated applications.

Surface area treatments, such as anodizing and polishing, are utilized to enhance deterioration resistance and boost aesthetic attributes. aluminum casting company. Anodizing, in specific, offers a protective oxide layer, making the aluminum extra resilient and aesthetically appealing

Upkeep Practices for Long Life

Implementing routine upkeep techniques is necessary for making sure the long life of aluminum factory items. Routine examinations should be performed to identify wear and tear, as very early detection can stop costly repair services and prolong the lifespan of parts. Cleansing equipment and equipment on a regular basis lessens the danger of contamination, which can detrimentally influence product high quality. Lubrication of relocating parts is additionally important, as it decreases rubbing and wear, enhancing operational performance.

In addition, the application of a preventative upkeep timetable aids in systematically resolving prospective concerns before they rise (aluminum metal casting). This consists of checking for leakages, ensuring appropriate placement, and calibrating equipment. Team training on appropriate handling and upkeep strategies cultivates a culture of care, which is important for maintaining product stability. Documenting upkeep tasks supplies beneficial insights into efficiency fads, allowing for notified decision-making regarding future maintenance techniques.

High Quality Control and Screening in Light Weight Aluminum Factory Manufacturing

Quality control and testing are extremely important in aluminum shop manufacturing, as they guarantee that last products fulfill defined requirements and customer assumptions. This process begins with resources evaluation, guaranteeing that aluminum alloys conform with required make-ups. Throughout the production cycle, in-process examinations are performed to monitor specifications like product, temperature level, and stress circulation.

When spreading is total, various tests-- such as dimensional checks, visual inspections, and non-destructive screening-- are performed to determine any kind of problems. Mechanical residential or commercial properties, consisting of tensile stamina and solidity, are assessed with standard screening methods.

Adherence to industry requirements, such as ISO and ASTM, is crucial for guaranteeing product quality. Statistical process control techniques are commonly employed to assess production data and facilitate continuous enhancement. By carrying out rigorous quality assurance steps, aluminum factories can enhance item dependability and lessen waste, eventually leading to better consumer fulfillment and operational effectiveness.

Regularly Asked Concerns

What Are the Ecological Effects of Light Weight Aluminum Factory Procedures?

Aluminum factory procedures can lead to significant environmental effects, including air pollution from emissions, water contamination from waste discharge, and power consumption adding to greenhouse gas discharges, eventually influencing local ecosystems and community health and wellness.

Exactly How Do Aluminum Prices Affect Factory Production Decisions?

Light weight aluminum rates significantly affect factory production choices; greater rates might lead to reduced result or raised effectiveness actions, while reduced rates can motivate expanded production and financial investment in new innovations to improve competitiveness and profitability.

What Precaution Are Vital in Aluminum Foundries?

Vital safety and security measures in aluminum factories consist of protective gear, correct ventilation to reduce breathing of fumes, routine equipment upkeep, training on emergency situation procedures, and adherence to safety and security procedures to stop crashes and injuries among employees.

Can Light Weight Aluminum Be Recycled, and How Is It Refined?

Aluminum can without a doubt be recycled. The procedure includes collection, melting, and reforming the product right into new items, considerably reducing power intake and ecological impact contrasted to primary aluminum manufacturing while protecting worldly top quality.

What Prevail Defects in Aluminum Spreading and Their Reasons?

The manufacturing procedure for light weight aluminum factory products is elaborate and needs a complete understanding of multiple stages. Light weight aluminum factory products are critical elements in various industries, providing a blend of light-weight stamina and rust resistance. The melting procedure is an essential action in the production of light weight aluminum factory products, as it changes strong light weight aluminum right into a liquified state suitable for spreading. Applying regular maintenance techniques is important for making certain the longevity of aluminum shop products. Quality control and testing are paramount in aluminum foundry manufacturing, as they assure that last items fulfill defined criteria and consumer expectations.